Physical AI for Manufacturers

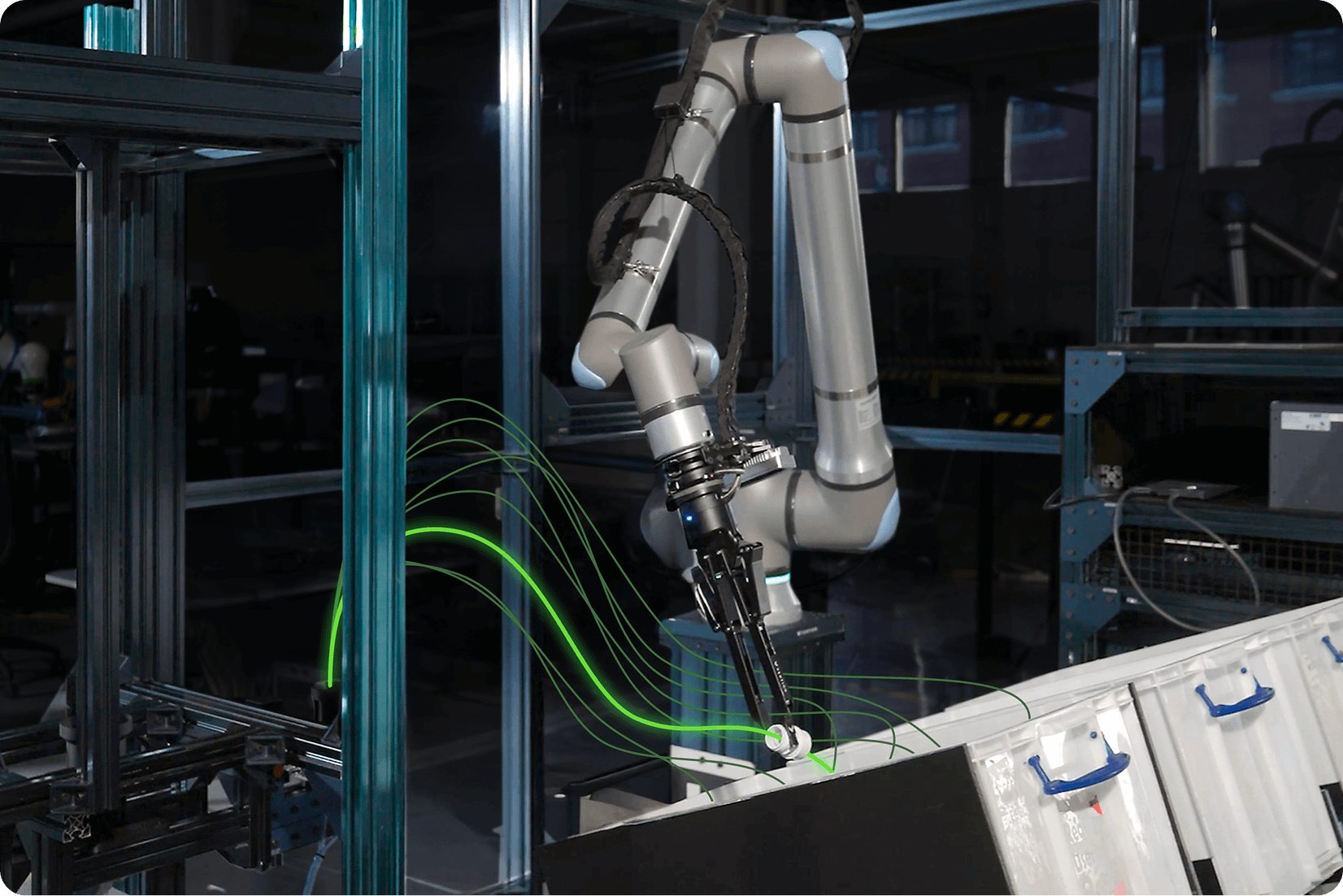

GRIIP™ (Generalized Robotic Industrial Intelligence Pipeline) is an end-to-end Physical AI pipeline that powers robots to perceive, reason, and act across unstructured tasks and unpredictable manufacturing environments.

Beyond Traditional Automation

Unlocking Manufacturing's Next Frontier

Unstructured manufacturing tasks have resisted automation because existing solutions can't handle real-world complexity. GRIIP makes the impossible possible by solving fundamental challenges that have defined the limits of robotic automation.

End-to-End Intelligence

Traditional robots fail with part variation and clutter. GRIIP handles perception to collision-free motion, adapting to complexity without custom programming.

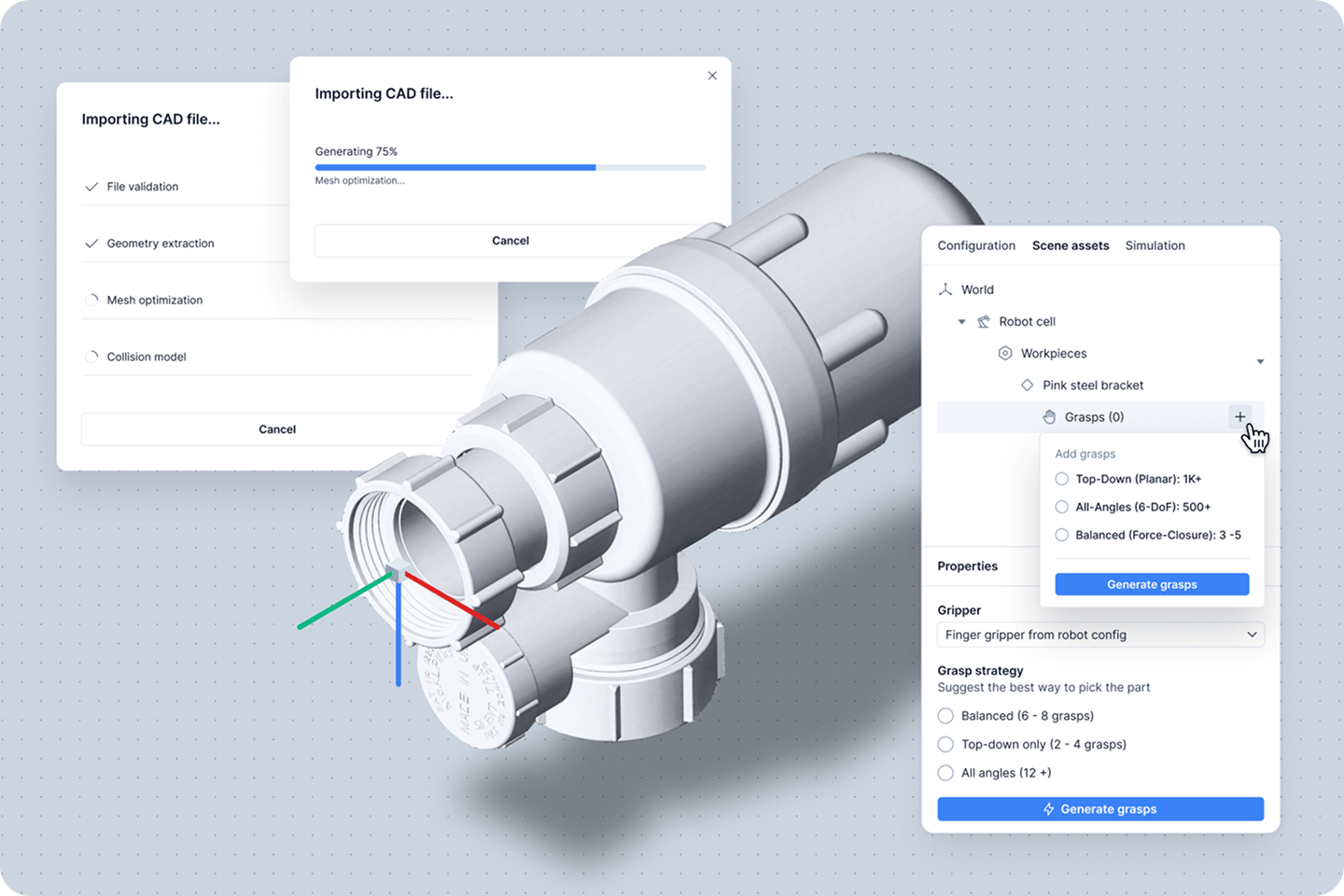

Zero Training Required

Conventional systems need weeks of data collection and teaching. GRIIP works out of the box with no training data. Upload CAD files and start picking in minutes.

Scalable AI Platform

Each application traditionally requires custom engineering. GRIIP's generalized pipeline deploys across tasks for faster projects, higher ROI, and design reuse.

Why GRIIP

Built for Manufacturing at Scale

Engineered for the demands of manufacturing reality, delivering adaptability without sacrificing speed or reliability. GRIIP handles variation while maintaining the performance standards production demands.

Built for Variety

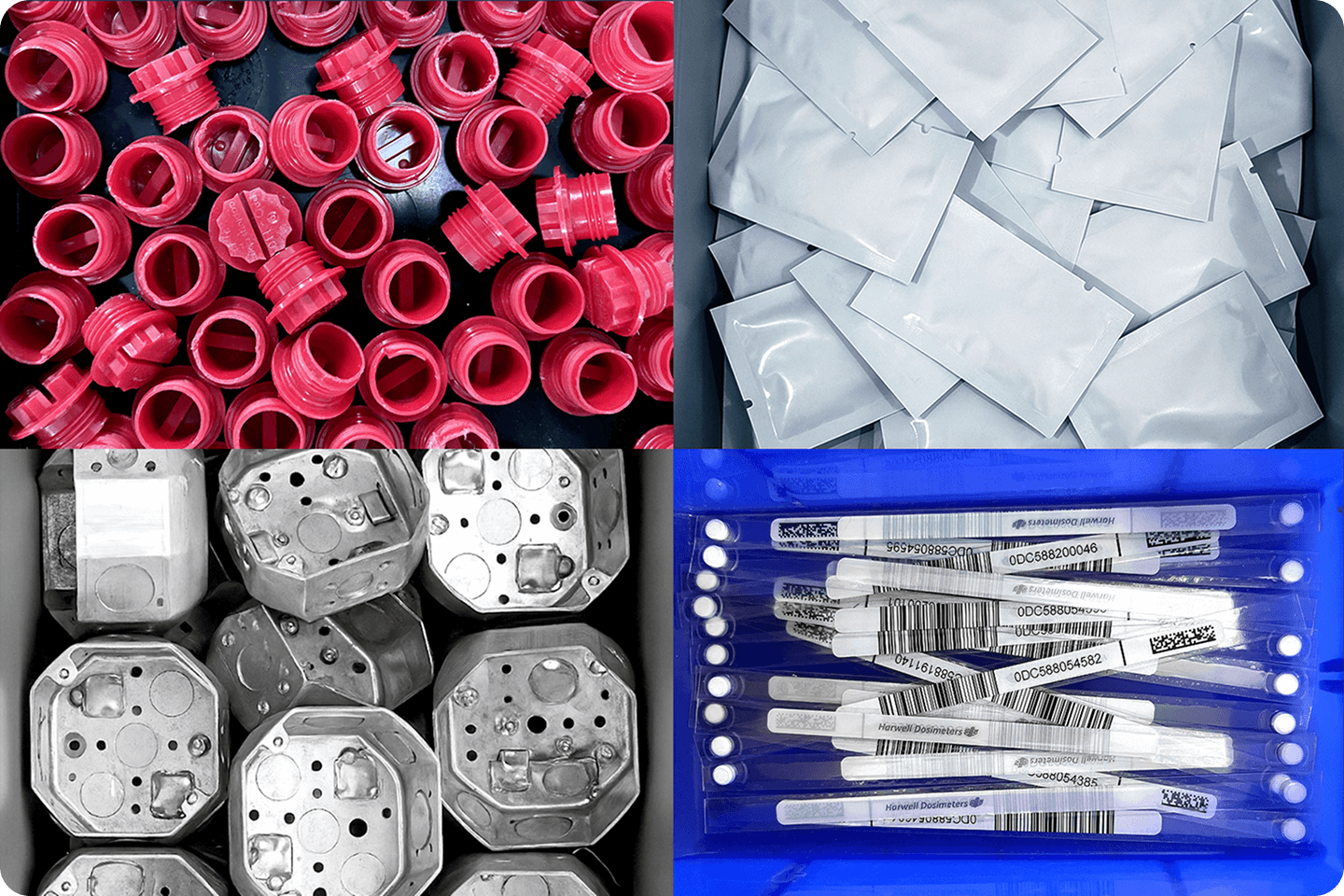

Works With Any Part

Adapts to diverse part geometries, materials, textures, and transparency without custom training. Handles mixed SKUs and new parts without part-specific programming.

Speed to Production

From CAD to Pick in Minutes

Works out of the box with no training data or datasets. Automated setup eliminates lengthy commissioning. Deploy robot cells in hours and add parts in minutes.

Resilience to Change

Built for Manufacturing Reality

Maintains reliable performance despite changes in lighting, workspace layouts, and environmental factors. Handles clutter, occlusions, and dynamic conditions autonomously.

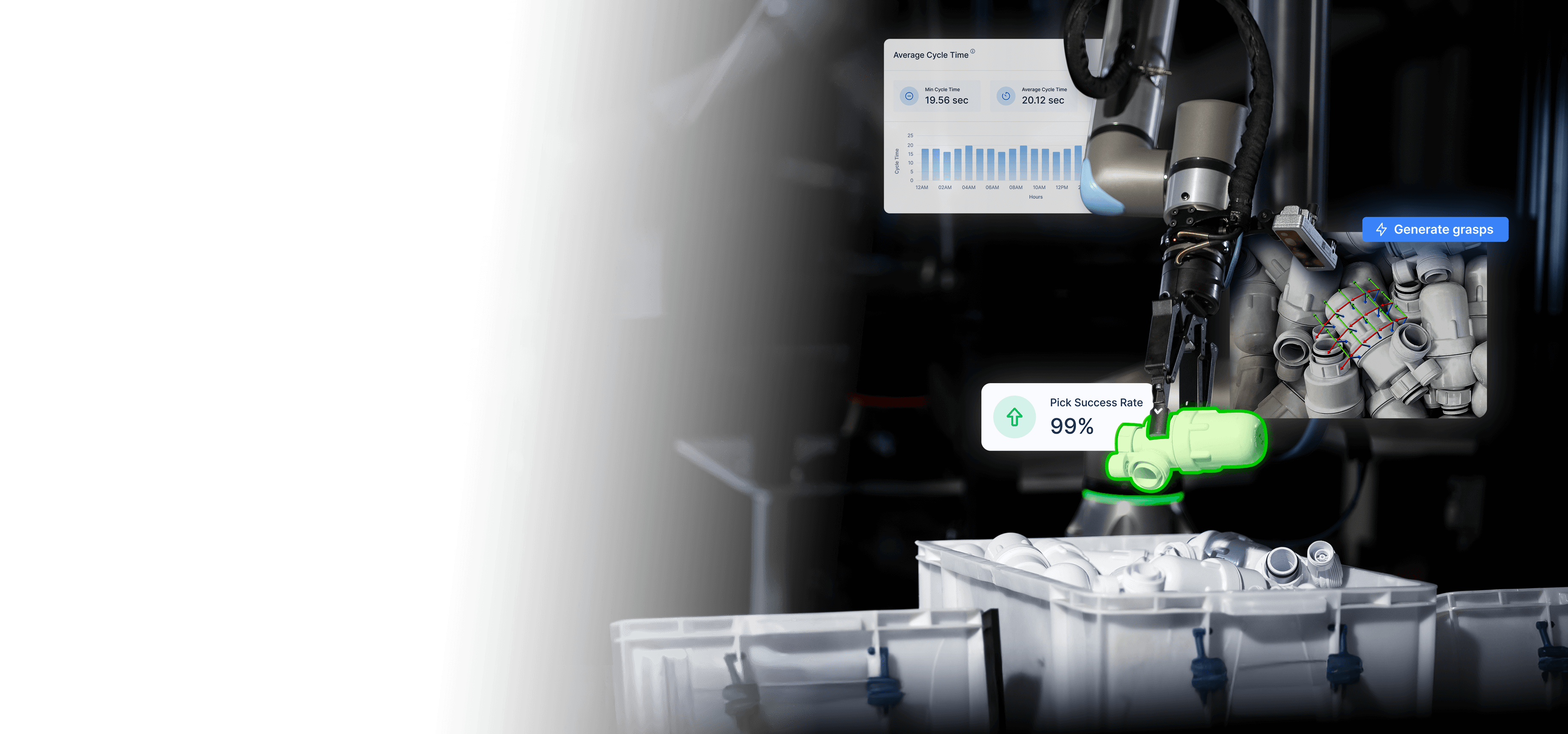

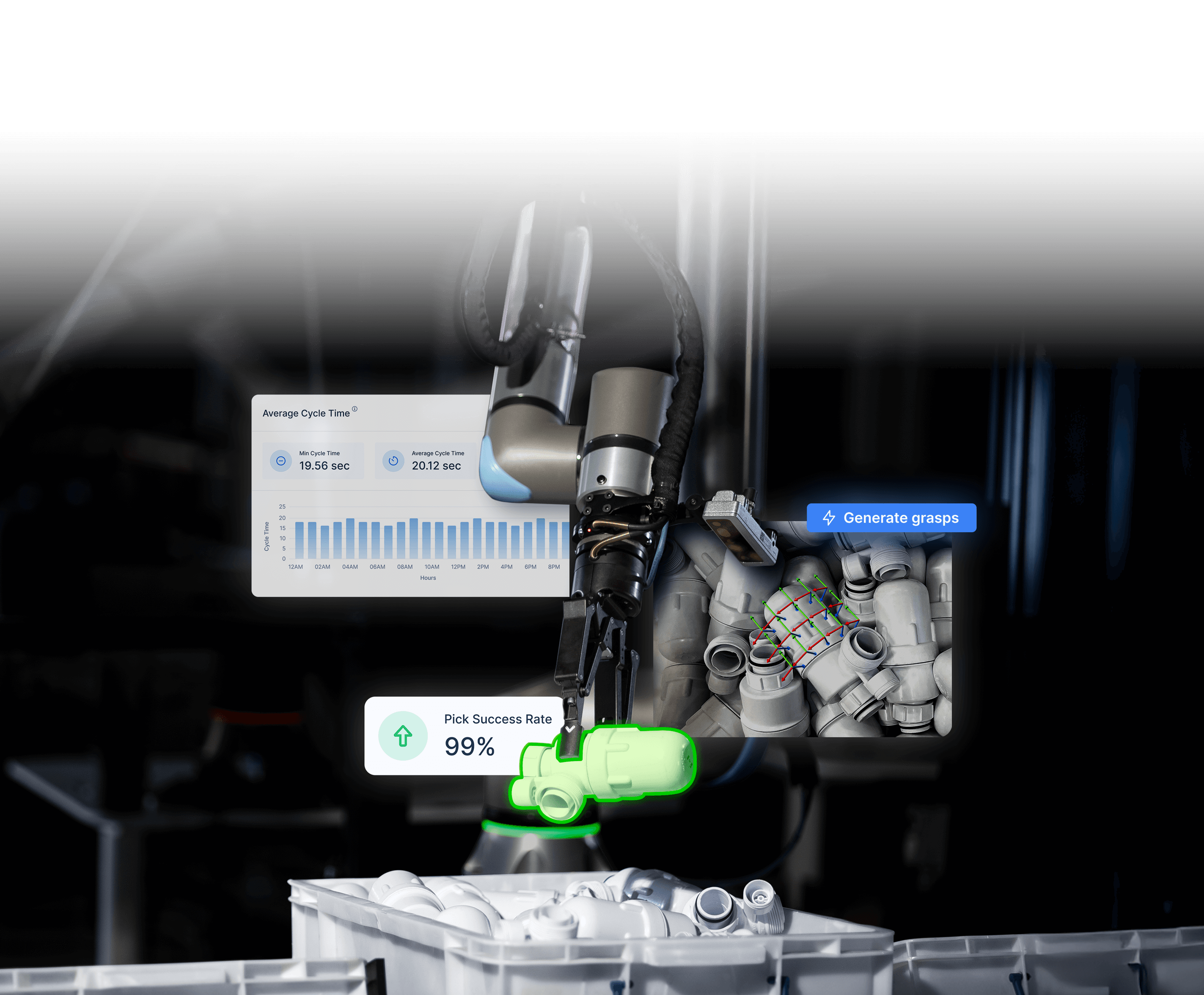

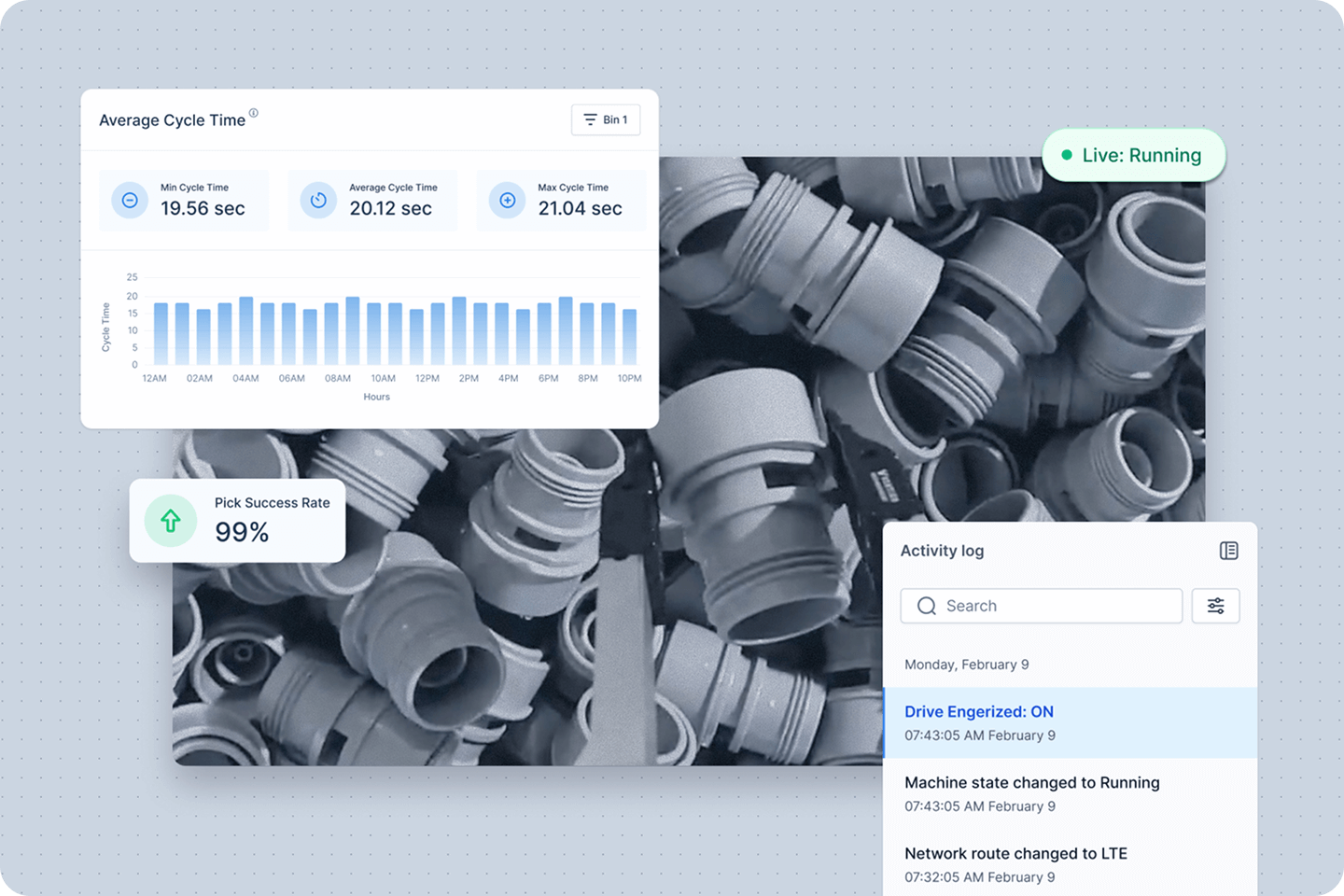

Production-Ready Reliability

Consistent Performance at Scale

Maintains 99% pick success rates and predictable cycle times. Delivers stability to meet targets while adapting to variation that breaks traditional automation.

Breaking Down the Pipeline

Generalized Physical AI for Manufacturing

A unified pipeline from perception to motion, designed to evolve continuously. The architecture always leverages state-of-the-art foundation models, improving performance over time without hardware upgrades or manual intervention.

Perception & Segmentation

Transforms visual input into structured understanding by detecting and segmenting objects in the workspace.

Segments objects in cluttered, unstructured environments

Adapts to varying part geometries and material properties

Maintains performance across changing light conditions

Perception & Segmentation

Transforms visual input into structured understanding by detecting and segmenting objects in the workspace.

Segments objects in cluttered, unstructured environments

Adapts to varying part geometries and material properties

Maintains performance across changing light conditions

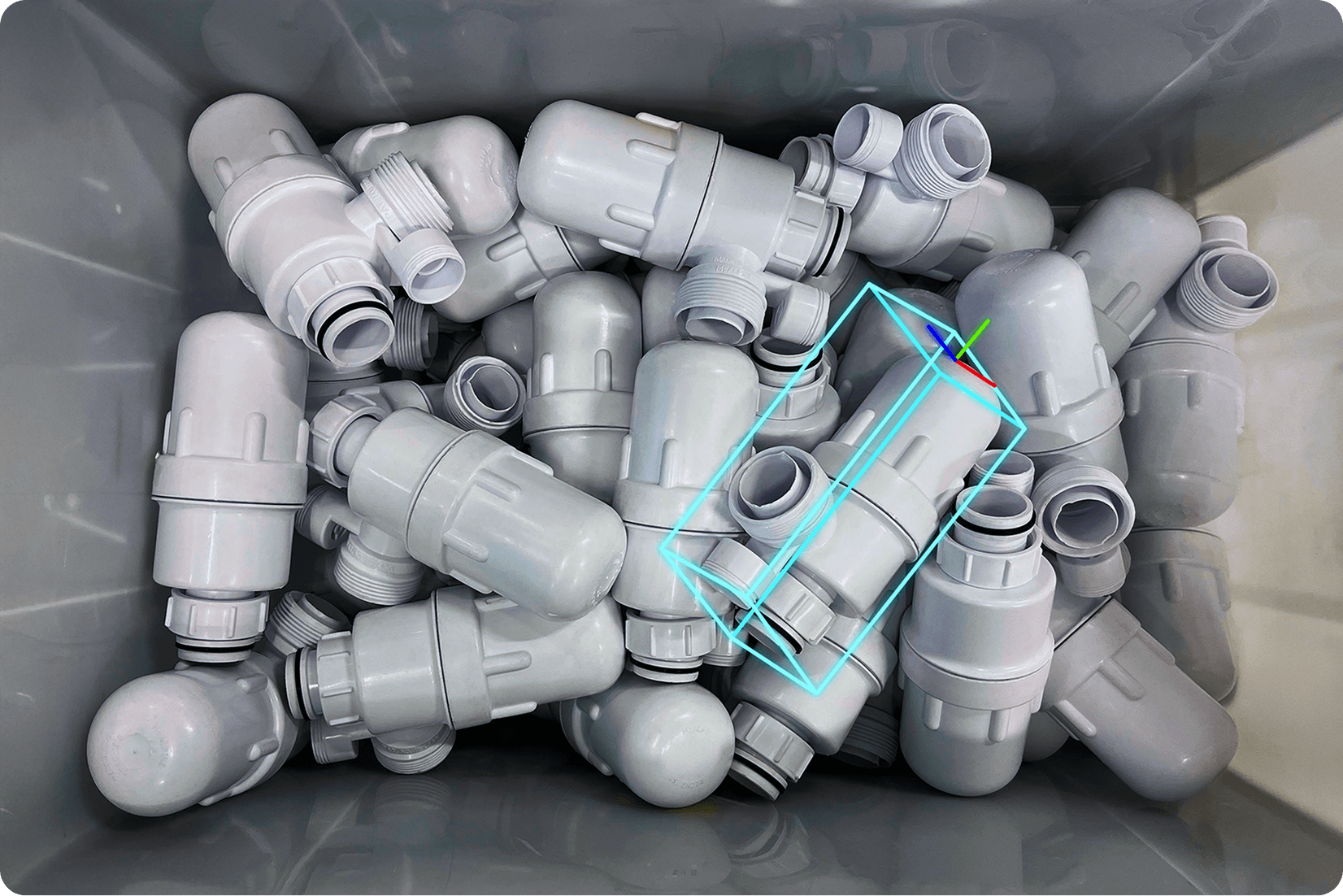

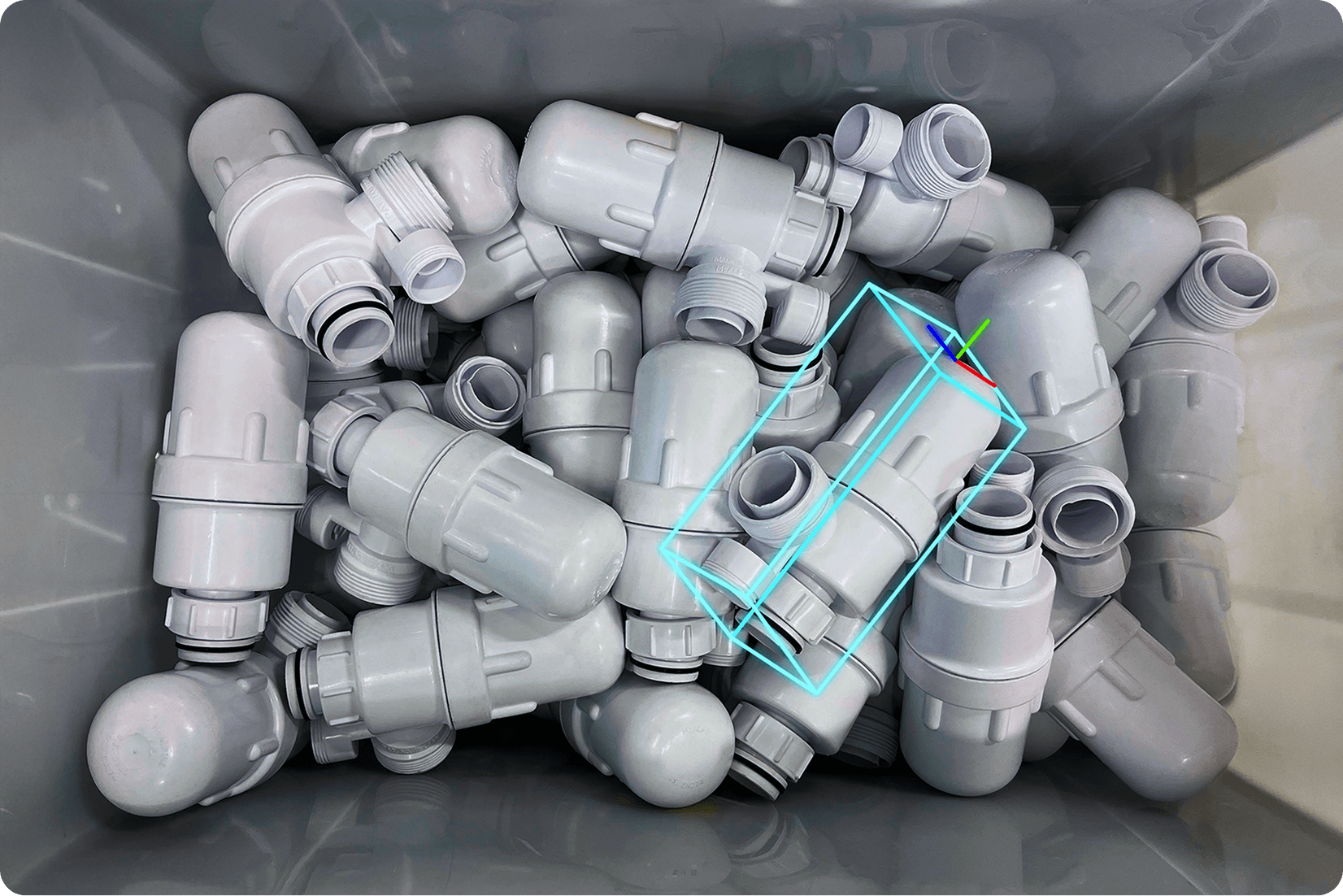

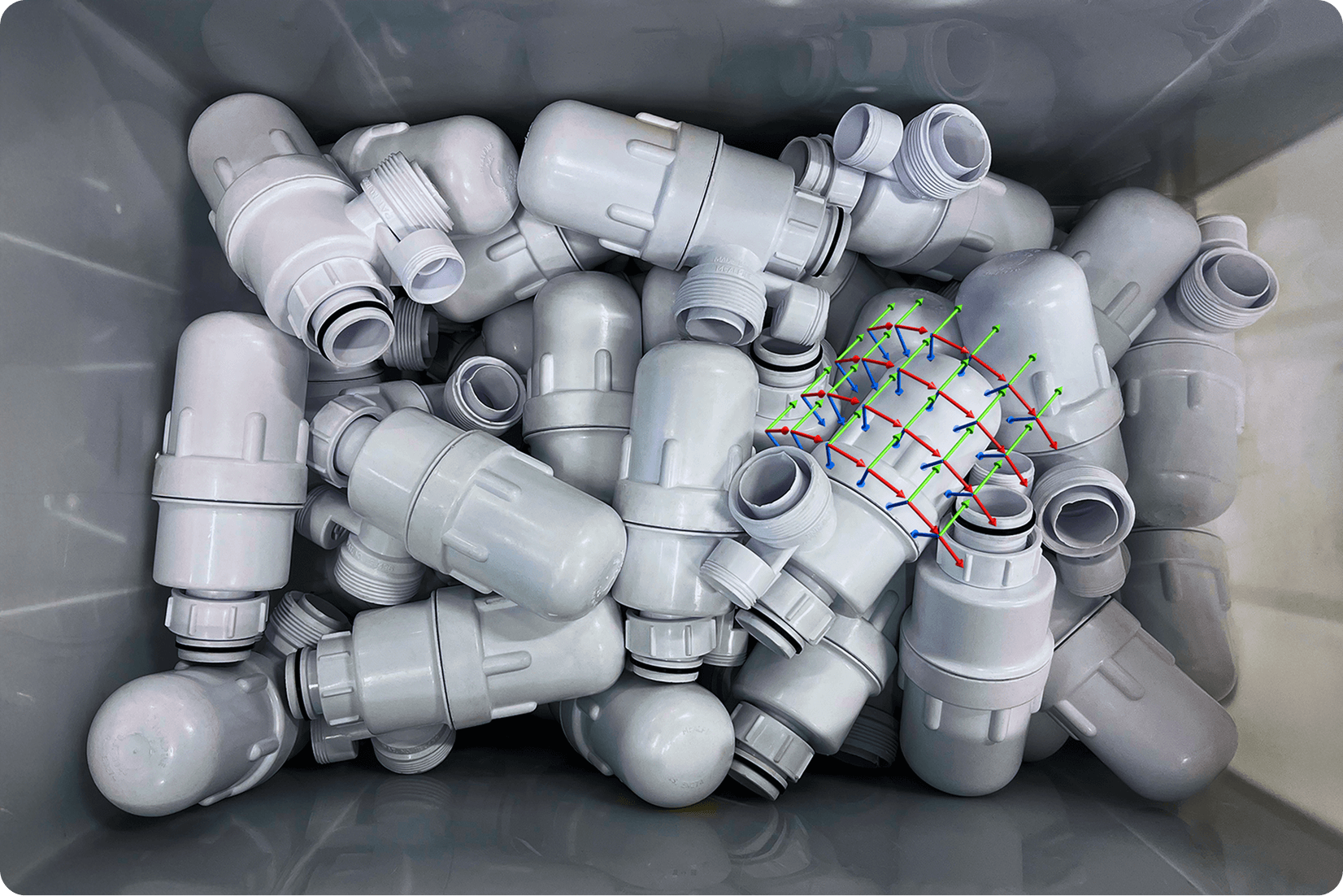

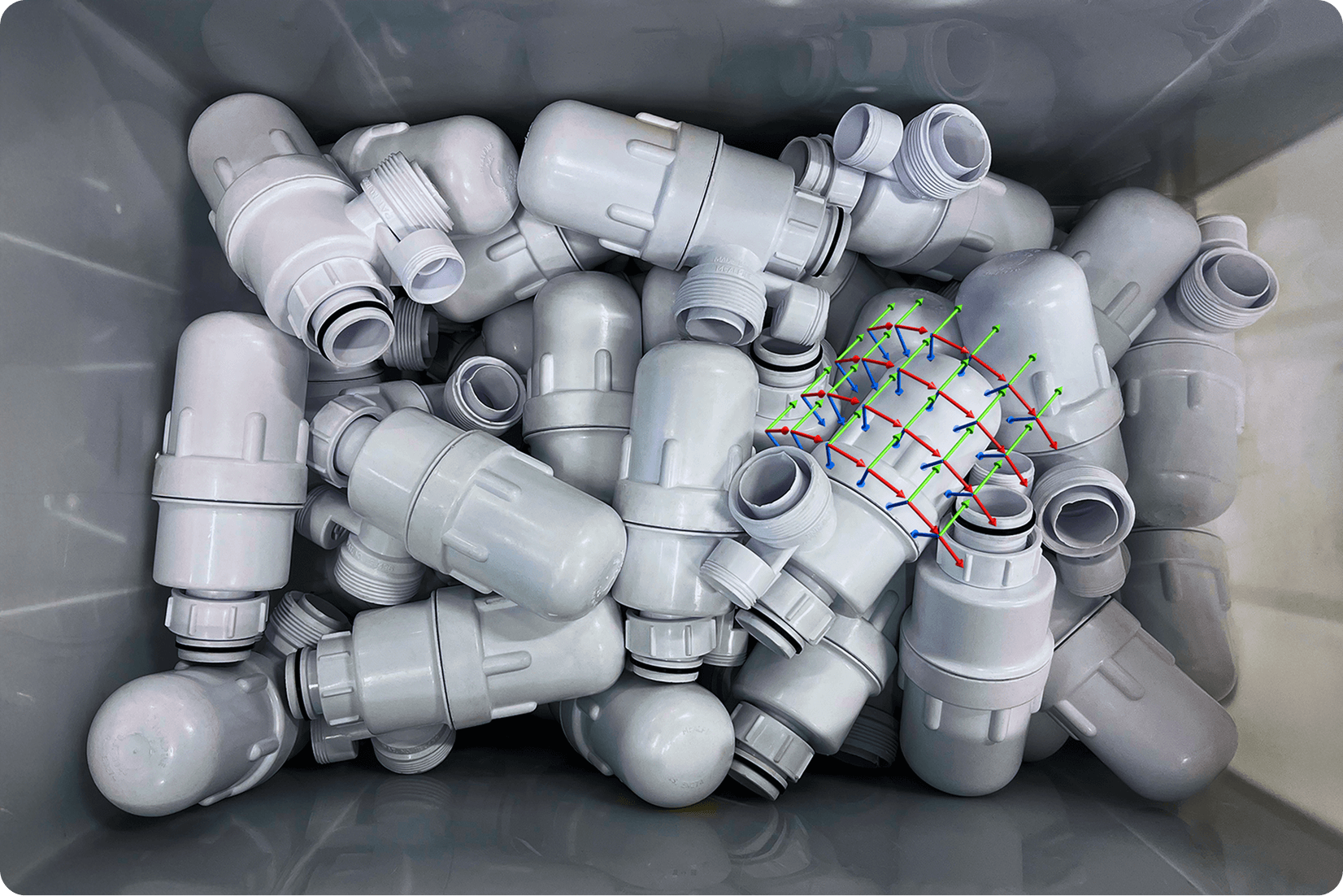

Pose Estimation

Estimates object orientation and position with sub-millimeter accuracy throughout the manipulation lifecycle, from pre-grasp to in-hand.

Provides 6DOF pose estimation for grasp point calculation

Tracks object pose during manipulation for stable handling

Adapts in real-time to object movement and shifts

Pose Estimation

Estimates object orientation and position with sub-millimeter accuracy throughout the manipulation lifecycle, from pre-grasp to in-hand.

Provides 6DOF pose estimation for grasp point calculation

Tracks object pose during manipulation for stable handling

Adapts in real-time to object movement and shifts

Grasp Intelligence

Analyzes the scene to identify, evaluate, and rank hundreds of grasp points for optimal object manipulation.

Evaluates hundreds of grasp candidates in seconds

Handles random orientations, mixed parts, and variation

Maximizes pick success rates with minimal manual tuning

Grasp Intelligence

Analyzes the scene to identify, evaluate, and rank hundreds of grasp points for optimal object manipulation.

Evaluates hundreds of grasp candidates in seconds

Handles random orientations, mixed parts, and variation

Maximizes pick success rates with minimal manual tuning

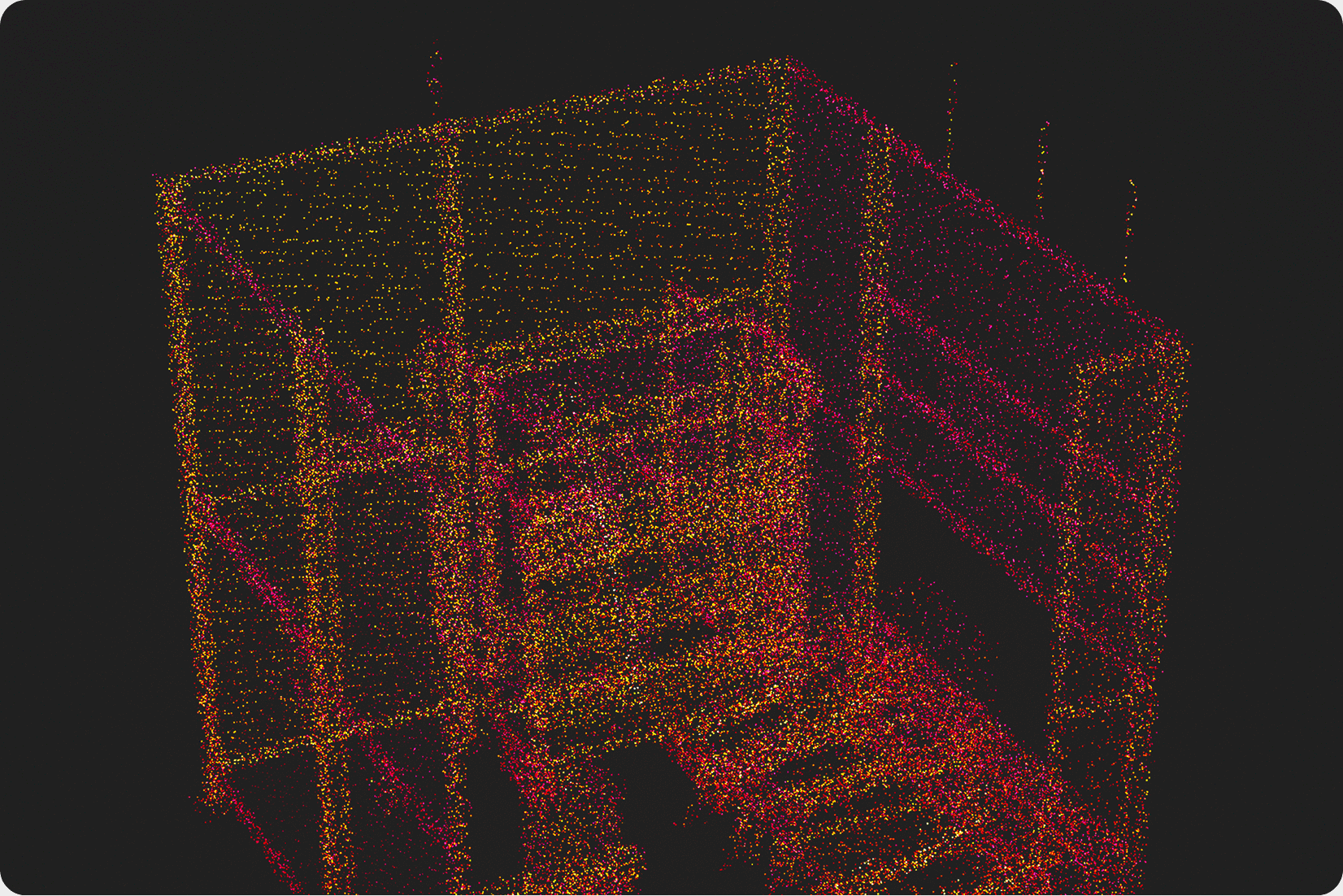

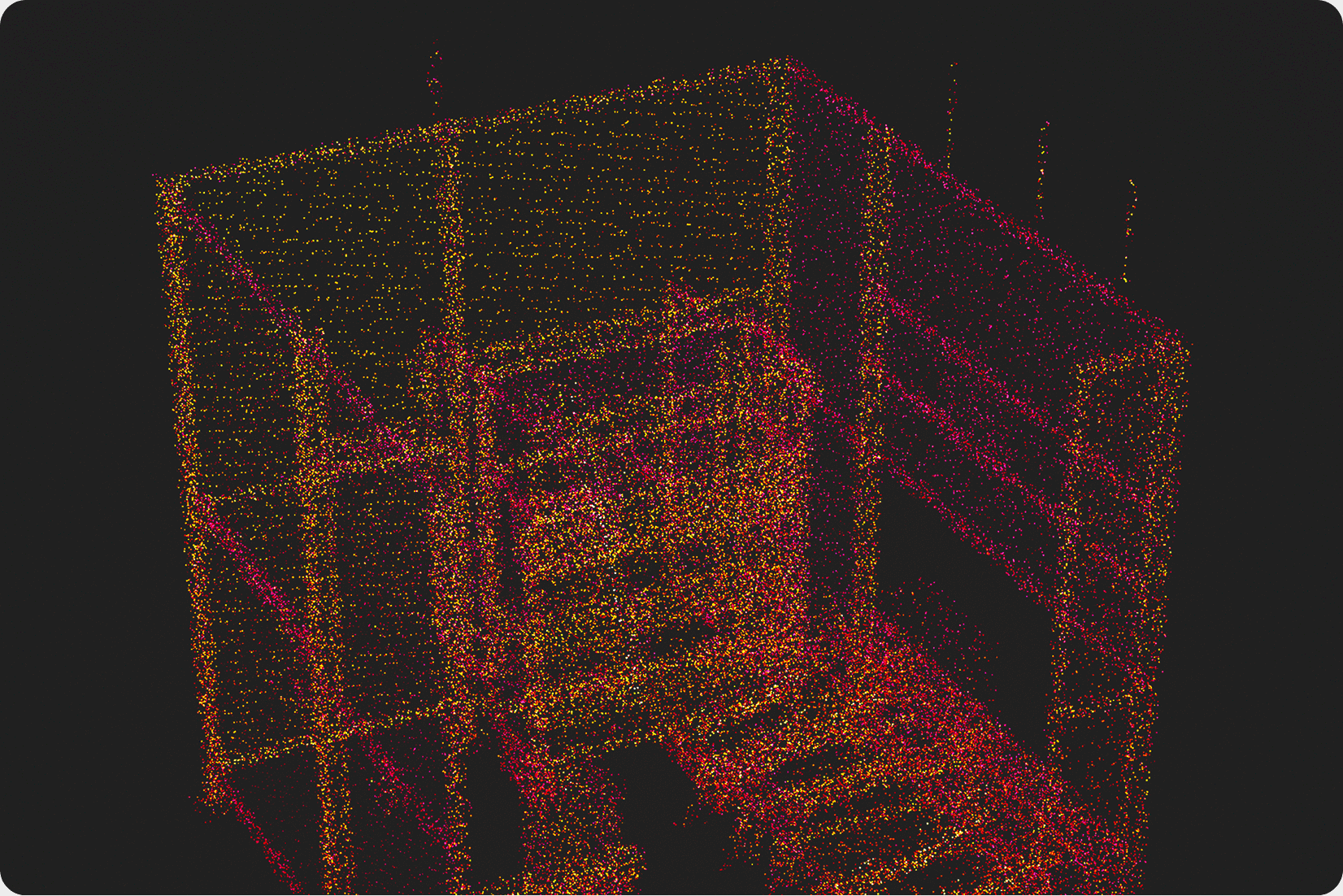

Scene Digitization & Calibration

Builds and maintains a digital representation of the robot's environment for accurate spatial reasoning.

Automatically digitalizes workspace geometry and limits

Calibrates transformations for reliable motion execution

Enables faster deployment with reduced commissioning

Scene Digitization & Calibration

Builds and maintains a digital representation of the robot's environment for accurate spatial reasoning.

Automatically digitalizes workspace geometry and limits

Calibrates transformations for reliable motion execution

Enables faster deployment with reduced commissioning

Collision-Free Path Planning

Plans and executes robot motion by generating unique trajectories for each pick based on real-time conditions.

Computes collision-free paths through kinematic filtering

Adapts each motion plan to the actual grasp configuration

Recalculates trajectories as environments and layouts shift

Collision-Free Path Planning

Plans and executes robot motion by generating unique trajectories for each pick based on real-time conditions.

Computes collision-free paths through kinematic filtering

Adapts each motion plan to the actual grasp configuration

Recalculates trajectories as environments and layouts shift

Applications Powered by GRIIP

One AI Pipeline. Endless Manufacturing Use Cases.

Where traditional robotics demands custom engineering per task, GRIIP deploys the same AI foundation across diverse manufacturing workflows. One system, multiple applications, zero task-specific programming.

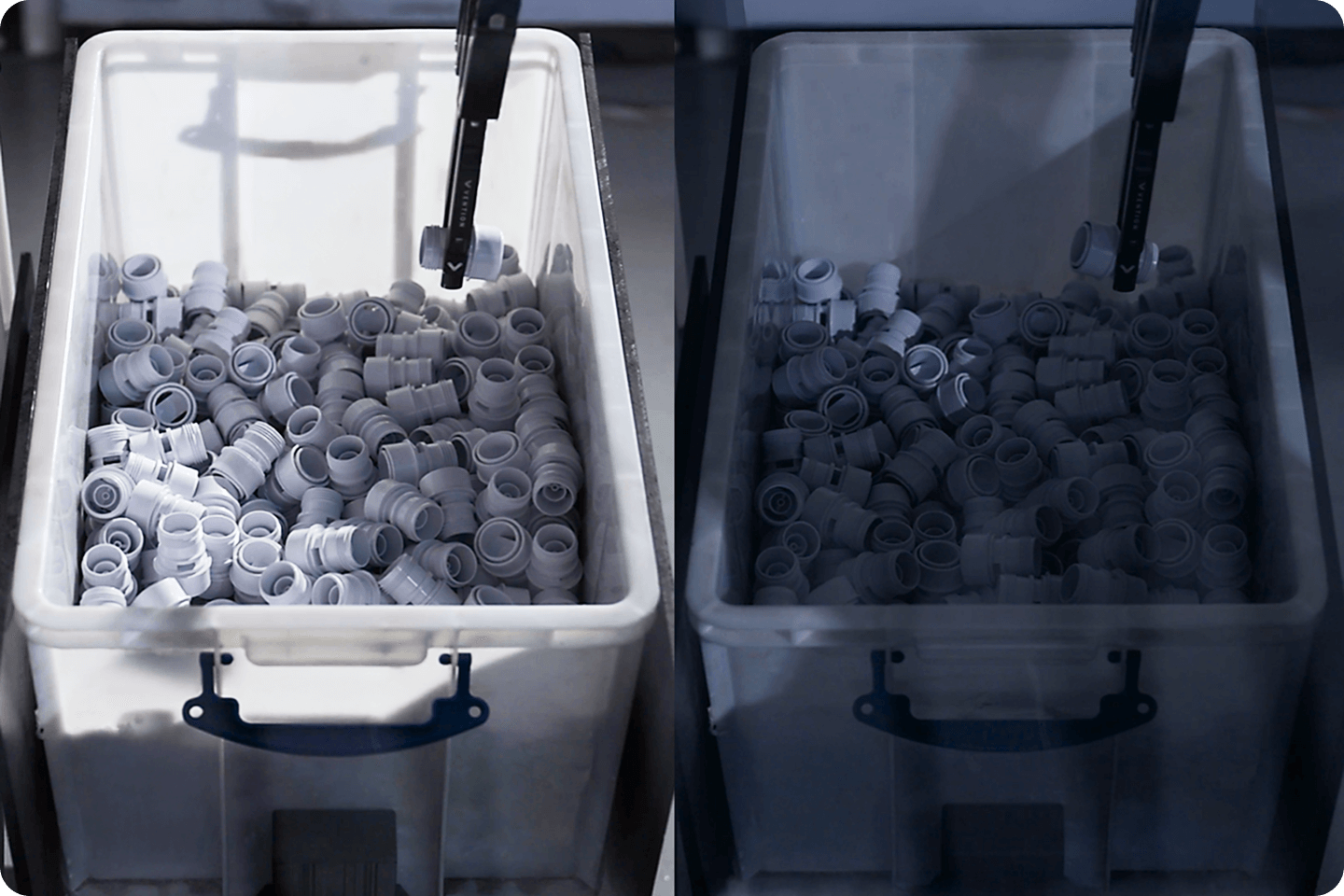

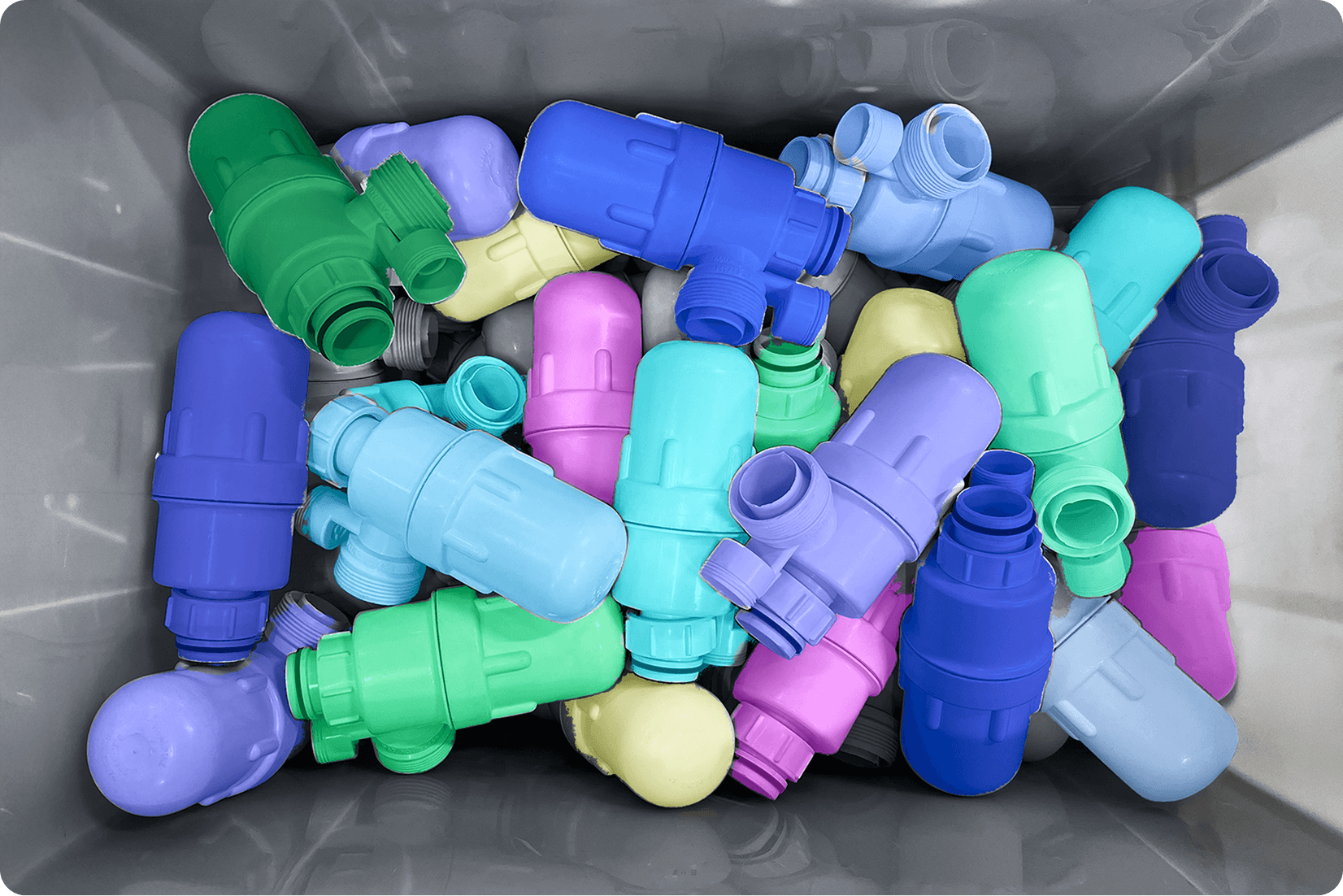

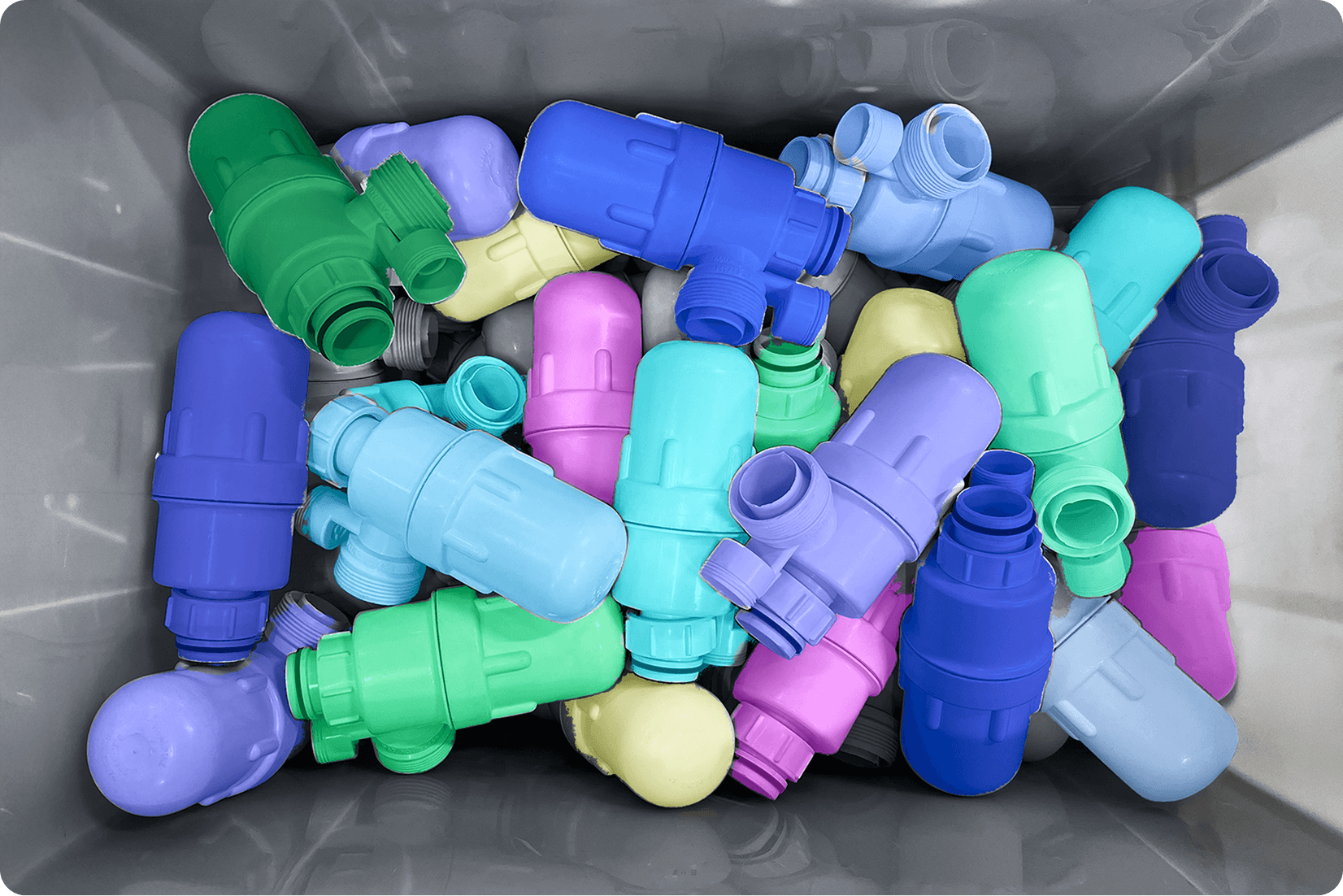

Bin Picking

Pick randomly oriented parts from deep bins with high reliability. Handles mixed SKUs, varying geometries, and cluttered scenes without programming.

Conveyor Pick & Place

Track and pick moving parts from conveyors with precision. Handles variable positioning and changing speeds without recalibration.

Kitting

Assemble kits by picking and placing multiple part types into trays. Adapts to different components and configurations automatically.

Depalletizing

Unload parts from pallets with varying stack patterns and orientations. Handles mixed loads and adapts to different pallet configurations automatically.

Sanding

Execute precise surface finishing tasks on complex geometries. Adapts tool paths to actual part poses and surface variations for consistent quality.

Machine Tending

Load and unload parts for CNC machines, presses, and other equipment. Adapts to part variation and changing orientations while maintaining consistent cycle times.

Get Started

Evaluate GRIIP for Your Application

Connect with our manufacturing AI experts to explore how GRIIP can automate your unstructured tasks. We'll evaluate your specific parts and processes to demonstrate the technology in action.